I quite like Spiderman movies, and having the ability to fire a web at a distant object or villain has its appeal. Since he fires web from his forearm, it must be lightweight to withstand the recoil, and to fire enough to hold his weight while he swings, it would need to have extremely strong fibers. It is therefore pretty obvious that the material of choice when we build such a thing will be graphene, which is even stronger than spider silk (though I suppose a chemical ejection device making spider silk might work too). A thin graphene thread is sufficient to hold him as he swings so it could fit inside a manageable capsule.

So how to eject it?

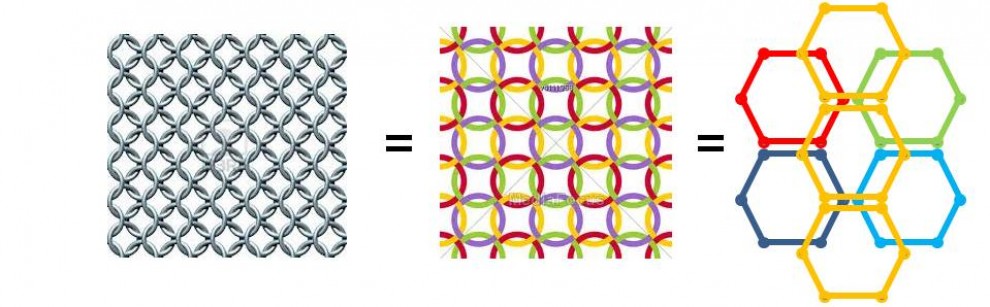

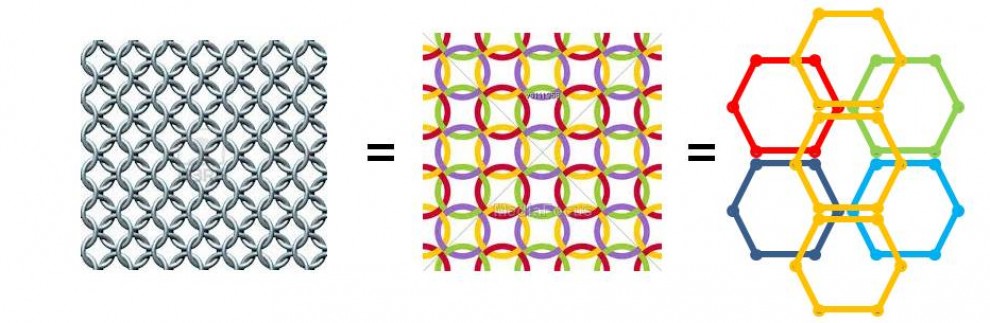

One way I suggested for making graphene threads is to 3D print the graphene, using print nozzles made of carbon nanotubes and using a very high-speed modulation to spread the atoms at precise spacing so they emerge in the right physical patterns and attach appropriate positive or negative charge to each atom as they emerge from the nozzles so that they are thrown together to make them bond into graphene. This illustration tries to show the idea looking at the nozzles end on, but shows only a part of the array: It doesn’t show properly that the nozzles are at angles to each other and the atoms are ejected in precise phased patterns, but they need to be, since the atoms are too far apart to form graphene otherwise so they need to eject at the right speed in the right directions with the right charges at the right times and if all that is done correctly then a graphene filament would result. The nozzle arrangements, geometry and carbon atom sizes dictate that only narrow filaments of graphene can be produced by each nozzle, but as the threads from many nozzles are intertwined as they emerge from the spinneret, so a graphene thread would be produced made from many filaments. Nevertheless, it is possible to arrange carbon nanotubes in such a way and at the right angle, so provided we can get the high-speed modulation and spacing right, it ought to be feasible. Not easy, but possible. Then again, Spiderman isn’t real yet either.

It doesn’t show properly that the nozzles are at angles to each other and the atoms are ejected in precise phased patterns, but they need to be, since the atoms are too far apart to form graphene otherwise so they need to eject at the right speed in the right directions with the right charges at the right times and if all that is done correctly then a graphene filament would result. The nozzle arrangements, geometry and carbon atom sizes dictate that only narrow filaments of graphene can be produced by each nozzle, but as the threads from many nozzles are intertwined as they emerge from the spinneret, so a graphene thread would be produced made from many filaments. Nevertheless, it is possible to arrange carbon nanotubes in such a way and at the right angle, so provided we can get the high-speed modulation and spacing right, it ought to be feasible. Not easy, but possible. Then again, Spiderman isn’t real yet either.

The ejection device would therefore be a specially fabricated 3D print head maybe a square centimeter in area, backed by a capsule containing finely powdered graphite that could be vaporized to make the carbon atom stream through the nozzles. Some nice lasers might be good there, and some cool looking electronic add-ons to do the phasing and charging. You could make this into one heck of a cool gun.

How thick a thread do we need?

Assuming a 70kg (154lb) man and 2g acceleration during the swing, we need at least 150kg breaking strain to have a small safety margin, bearing in mind that if it breaks, you can fire a new thread. Steel can achieve that with 1.5mm thick wire, but graphene’s tensile strength is 300 times better than steel so 0.06mm is thick enough. 60 microns, or to put it another way, roughly 140 denier, although that is a very quick guess. That means roughly the same sort of graphene thread thickness is needed to support our Spiderman as the nylon used to make your backpack. It also means you could eject well over 10km of thread from a 200g capsule, plenty. Happy to revise my numbers if you have better ones. Google can be a pain!

How fast could the thread be ejected?

Let’s face it. If it can only manage 5cm/s, it is as much use as a chocolate flamethrower. Each bond in graphene is 1.4 angstroms long, so a graphene hexagon is about 0.2nm wide. We would want our graphene filament to eject at around 100m/s, about the speed of a crossbow bolt. 100m/s = 5 x 10^11 carbon atoms ejected per second from each nozzle, in staggered phasing. So, half a terahertz. Easy! That’s well within everyday electronics domains. Phew! If we can do better, we can shoot even faster.

We could therefore soon have a graphene filament ejection device that behaves much like Spiderman’s silk throwers. It needs some better engineers than me to build it, but there are plenty of them around.

Having such a device would be fun for sports, allowing climbers to climb vertical rock faces and overhangs quickly, or to make daring leaps and hope the device works to save them from certain death. It would also have military and police uses. It might even have uses in road accident prevention, yanking pedestrians away from danger or tethering cars instantly to slow them extra quickly. In fact, all the emergency services would have uses for such devices and it could reduce accidents and deaths. I feel confident that Spiderman would think of many more exciting uses too.

Producing graphene silk at 100m/s might also be pretty useful in just about every other manufacturing industry. With ultra-fine yarns with high strength produced at those speeds, it could revolutionize the fashion industry too.