What would you do with a 600km high structure? That would be hundreds of times higher than the highest ever built so far. I think it is feasible. Here I will suggest super-light, super-strong building materials that can substitute for steel and concrete that can be grown up from the base using feasibly high pressures.

I recently proposed a biomimetic technique for printing graphene filaments to make carbon fur (- in this case, for my fictional carbon-obsessed super-heroine Carbon Girl. I am using the Carbon Trio as a nice fun way to illustrate a lot of genuine carbon-related concepts for both civil and military uses, since they could make a good story at some point. Don’t be put off by the fictional setting, the actual concepts are intended to be entirely feasible. Real science makes a better foundation for good science fiction. Anyway, this is the article on how to make carbon filaments, self-organised into fur, and hence her fur coat:)

http://carbondevices.com/2013/07/01/carbon-fur-biokleptic-warmth-and-protection/

Here is the only pic I’ve drawn so far of part of the filament print head face:

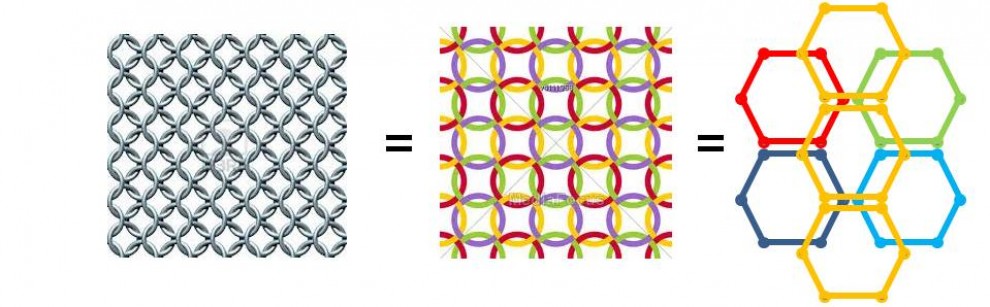

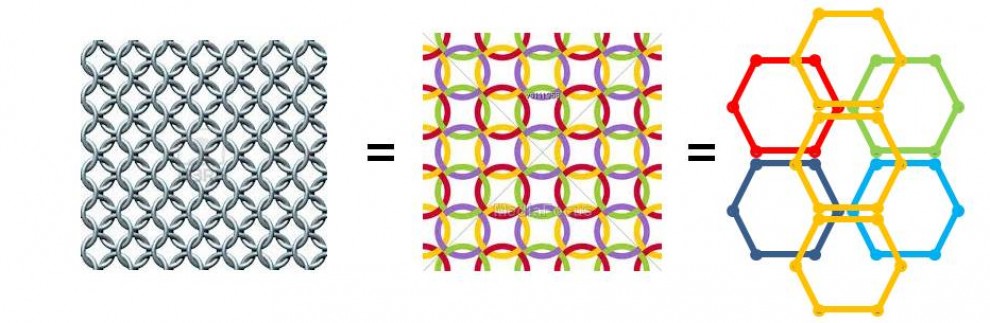

Many print heads would be spread out biomimetically over a scalable area as sparsely or densely as needed, just like fur follicles. A strong foundation with this print head on top could feasibly form the base of a very tall vertical column. If the concept as described in the fur link is adapted slightly to print the filaments into a graphene foam medium, (obviously pushed through the space between the follicles that produce the filaments) a very lightweight foam structure with long binding filaments of graphene graphene foam would result, that would essentially grow from the ground up. This could be very strong both in compression and tension, like a very fine-grained reinforced concrete, but with a tiny fraction of the weight. Given the amazing strength of graphene, it could be strong enough for our target 600km. Graphene foam is described here:

Extruding the supporting columns of a skyscraper from the ground up by hydraulically growing reinforced graphene foam would certainly be a challenging project. The highest hydraulic pressures today are around 1400 bar, 1.427 tonnes per sq cm. However, the density of graphene foam with graphene filament reinforcement could be set at any required density from below that of helium (for graphene spheres of 0.014mm with vacuum inside), to that of solid carbon if the spheres are just solid particles with no vacuum core. I haven’t yet calculated the maximum size of hollow graphene spheres that would be able to resist production pressures of 1400 bar. That would determine the overall density of the material and hence the maximum height achievable. However, even solid carbon columns only weigh 227g per metre height per sq cm of cross-section, so even that pressure would allow 6.3km tall solid columns to be hydraulically extruded. Lower densities of foam would give potentially large multiples of that.

This concrete substitute would be nowhere near as strong as basic graphene, but has the advantage that it could be grown.

(The overall listed strength of solid graphene theoretically allows up to 600km tall, which would take you well into space, perfect for launching satellites or space missions such as asteroid mining. But that is almost irrelevant, since graphene will also permit construction of the space elevator, and that solves that problem far better still. Still, space elevators would be very costly so maybe there is a place for super-tall ground-supported structures.)

But let’s look again at the pressures and densities. I think we can do a lot better than 6km. My own proposal a while back suggests how 30km tall structures could be built using graphene tube composite columns structures. I did think we’d be able to grow those.

Super-tall (30km) carbon structures (graphene and nanotube mesh)

We’d need higher pressures to extrude higher than 6km if we extruding solid columns, but these tube-based columns with graphene filament reinforced graphene foam packing would have a far lower density. The print heads in the above diagram were designed to make fur filaments but I think it is possible (though I haven’t yet done it) to redesign the print heads so that they could print the tubular structures needed for our columns. Tricky, but probably possible. The internal column structures are based on what nature uses to make trees, so are also nicely biomimetic. If we can redesign the print heads, then printing low density columns using a composite of filament reinforced foam, in between graphene tubes should work fine, up to heights well above the 30km I originally suggested. An outer low pressure foam layer can be added as the column emerges. It doesn’t have to withstand any significant pressure so can be as light as helium and add the strength needed to prevent column buckling. With the right structure, perhaps the whole 600km can be achieved that way. Certainly the figures look OK superficially, and there’s no hurry. It’s certainly worth more detailed study.

FUTURISTS open the mind to the most far-out possibilities, stimulate studies by level-headed implementers, and entertain us with their imagination, building bridges to the future of the possible.

LikeLike

Like the sound of moving on from concrete and steel

LikeLike

I have a curious idea I simply can’t find the answers too. If a 600km building connects the outer magnetic field with the surface wouldn’t that caused super lightning on a dangerous scale?

LikeLike