Very many devices have been designed over the years to harvest wave and tidal energy. Many are land based, using rising and falling tides or incoming waves. Some are off shore, but rely on tethers to the sea bed to harness the different water pressure between top and bottom of waves. A very few can be fully off shore and free floating, and use mechanical movements caused by waves or rely on waves crashing over slopes to fill chambers to get a small pressure difference to drive a generator.

I live near Woodbridge Tide Mill which has been working for 850 years and some years ago I had the idea of making tidal lagoons around wind farms or other sand banks, only to discover someone else already thought of it. Making tidal lagoons that float freely is obviously a problem, since they would rise and fall with the tide so there isn’t an obvious mechanism to extract the energy, hence the need for either putting them on a support or tethering them, both of which add cost and location issues.

This morning, on reading about a new blowhole generator, a great idea in itself, I was inspired to realise that the height differential and energy of incoming waves could easily be used to move a membrane or piston to push water out of a chamber where the pressure is lower. Therefore it could be used to fairly rapidly empty a large container, which would float up until the wave energy is no longer enough. Then the idea of the tide mill comes back, because there can also be an inner chamber that acts as a mill pond. After thinking for a while and toying with various ideas, I came up with a simple four phase system that uses an outer and inner chamber to store and use wave energy. It is called a virtual tide mill, because it makes the ‘tides’ by itself, using wave energy. They are totally unconnected to natural tides and could be of high frequency, depending on how good the waves are at the time.

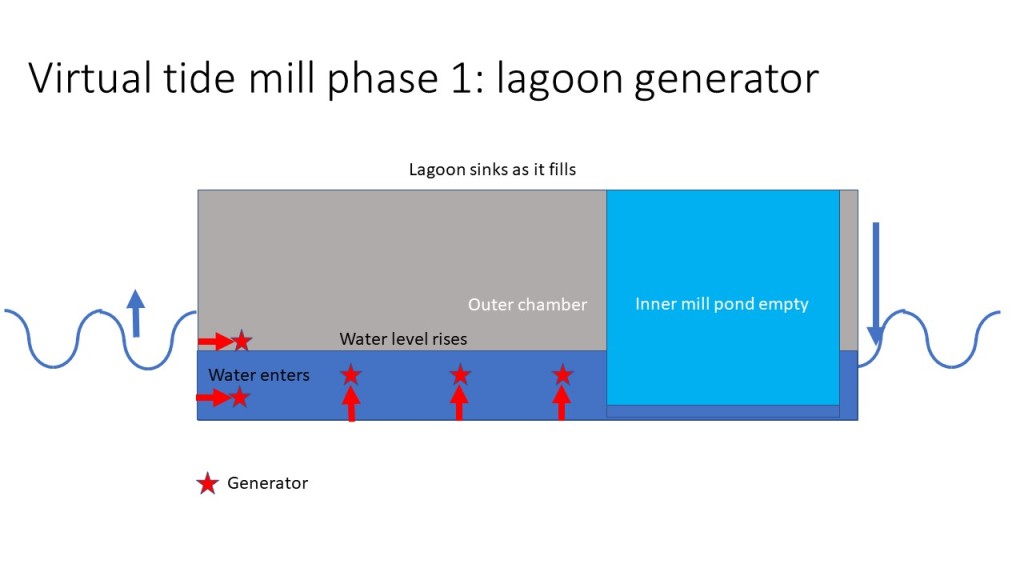

Phase 1 starts with both chambers empty, then the outer chamber sinks due to water flooding in through valves, generating power as it does, and a pressure differential with the mill pond would be created. That creates a useful energy store that can be used to drive a generator on demand. Once the outer chamber is nearly full, Phase 2 starts.

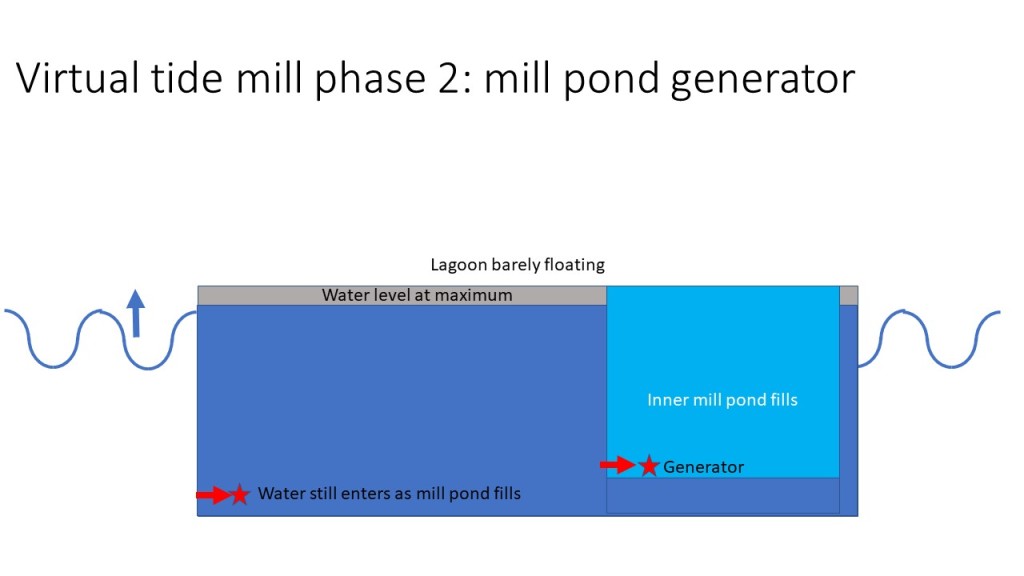

The mill pond valve would be opened and its generator would operate as the mill pond fills. As it does so, more water would naturally still enter the outer chamber, until the entire structure is barely floating.

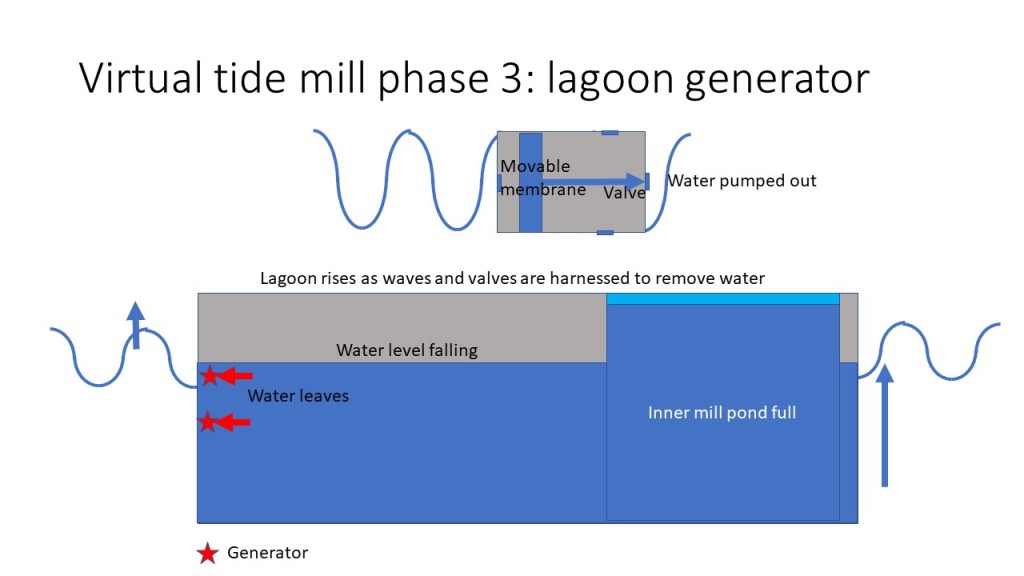

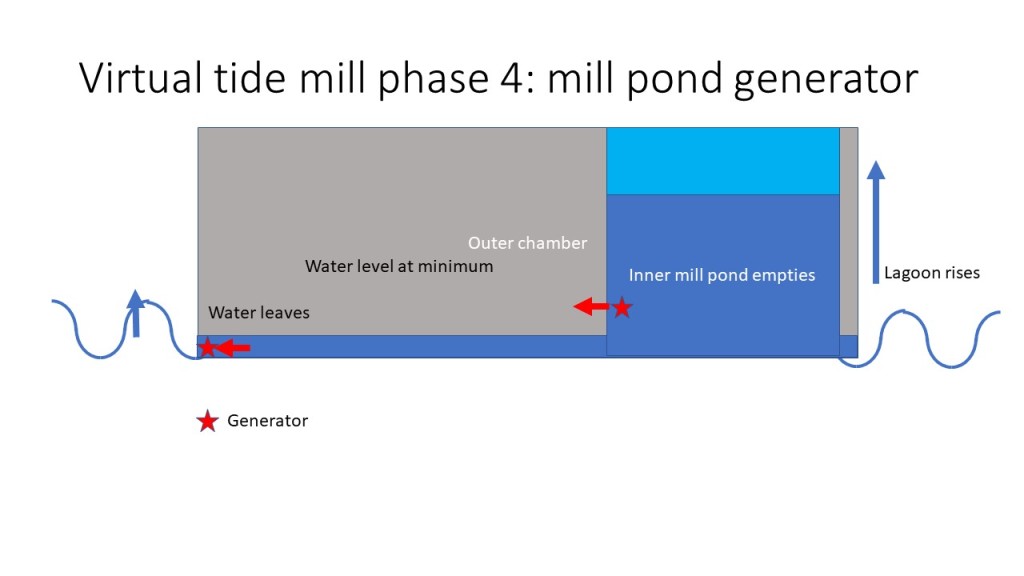

Phase 3 comprises using incoming wave energy and the pressure difference between wave crest and trough to move a membrane or piston and push water out of valve where pressure is lower, driving generators as it does. It is a simple pumping action and many designs could be used to implement it. This would continue until the entire structure is floating well again, but by then, the still-full mill pond would have a good pressure differential with the outer chamber, so Phase 4 uses that to drive generators as water leaves the mill pond.

The water moving into the outer chamber could be pumped out, driving generators, until the entire structure is empty again, floating as high as possible and ready to move back to Phase 1.

With so many diverse offerings in the field, competition would be pretty tough, but this system has some advantages over other schemes. It can be deployed anywhere so can be placed where the waves are strongest. With the hydrogen economy coming over the horizon, it could perhaps use the energy it makes to generate hydrogen, easily pumped into ships for transport anywhere, or if close enough to land (or wind farms), cables could be used to transfer electricity into the grid. Yet another purpose could be to power submerged server farm infrastructure (submerging solves cooling issues).

Secondly, the use of an inner ‘mill pond’ provides a good energy storage mechanism so that power can be generated when needed as well as continuously while the waves are good enough.

R&D would obviously be required to evaluate optimal design of pumps and generators. Pumps could be as simple as flexible membranes with valves, or use more complex piston arrangements. There could be two or many outer and inner chambers, and two or many bi-directional generators. The optimal sizes of outer chamber and mill pond would also presumably depend on wave size and materials available so again that needs R&D.

On the topic of renewable energy, you may be interested in my other ideas, the wind energy harvester and the hurricane harvester.